Page path:

- Mechanical and Process Engineering

- Research

- Laboratories

- Overview and descriptions

- Laboratory for Robotics, Production Automation and Geometry Simulation

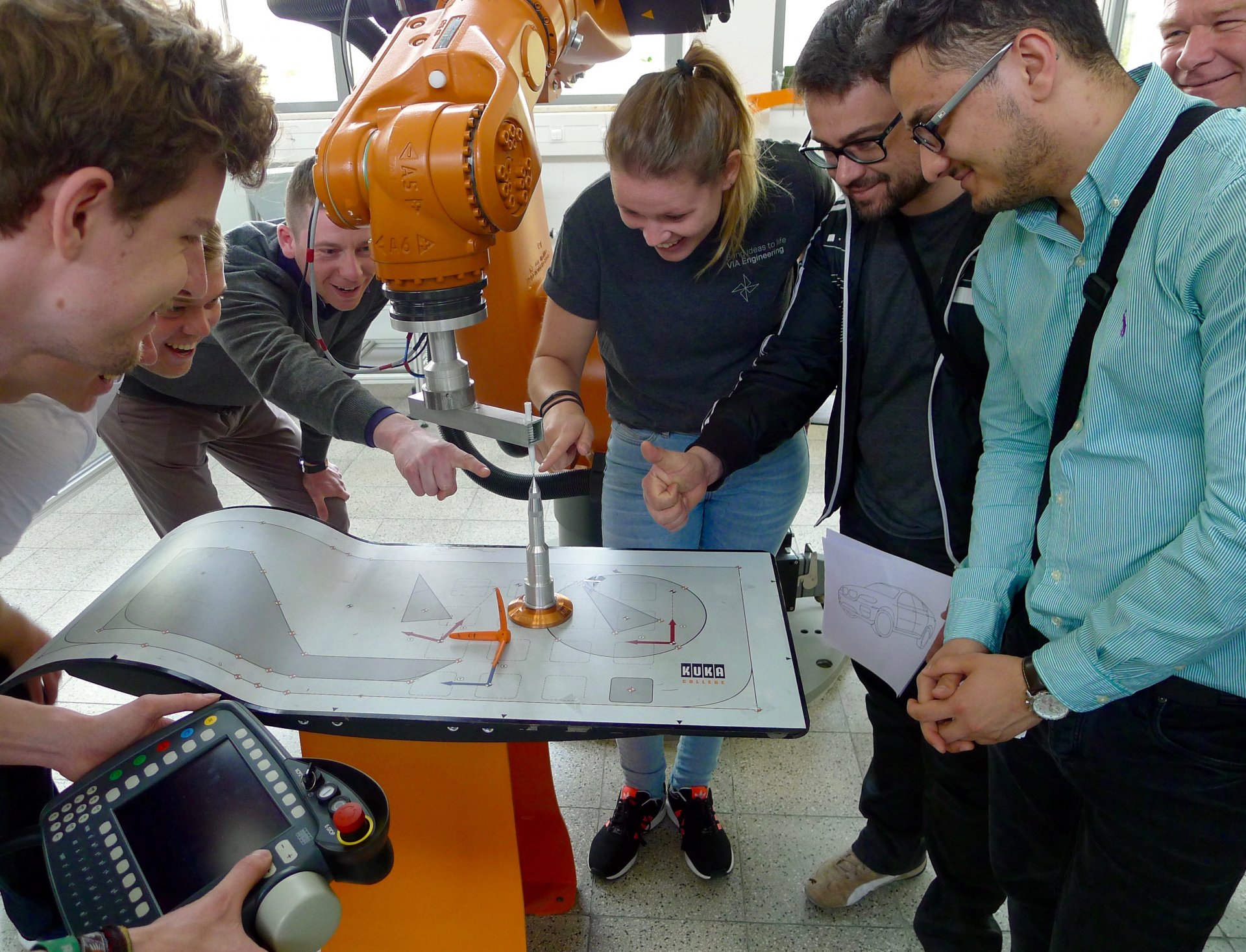

Laboratory for Robotics, Production Automation and Geometry Simulation

| Laboratory name | Laboratory for Robotics, Production Automation and Geometry Simulation |

| Abbreviated name | Robotics Laboratory |

| Academic leadership | Prof. Dr.-Ing. Eberhard Roos |

| Room | D 1.09 | D 1.11 | D 1.11a |

| Laboratory belongs to |

|

| Workstations |

|

| History | Robotics is one of the key technologies for lean and flexible production in Germany. Taking this development into account, the Robotics Laboratory was set up approximately 25 years ago by Prof. Dr. Lange at the Faculty of Mechanical Engineering in the old F Building. Since October 2003, the Robotics Laboratory has been led by Prof. Dr. Roos and expanded in the modernized D Building. A training partnership with the KUKA College of the KUKA Roboter GmbH company has been in place since 2005. |

| Tasks and objectives | The practical component of education in robotics, production automation and geometry simulation takes place in the Robotics Laboratory. The aim of the practical training in the laboratory is to familiarize the students with modern industrial robots, automation devices and 3D simulation systems and prepare them for their future careers in a practice-oriented manner. Approaches to this include the license for robots and the training to become a robot specialist (Certified Robot Engineer) in cooperation with KUKA Roboter GmbH. Additional tasks of the Robotics Laboratory include working on practical research and industrial projects in the context of project or thesis work. |

| Laboratory equipment |

|

Contact | |

Phone: | +49 821 5586-3198 |

Fax: | +49 821 5586-3160 |