This is an old revision of the document!

Making the plane waterproof for landing in the water

Finding the right glue

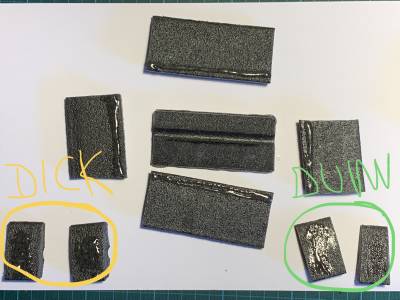

I tried 3 different glues. The model we use (mini talon) is made with “EPU” expandend PU.

I tried:

* UHU POR - special glue for Styropor and similar foams. * UHU Plus - 5 min two component epoxy * Hot Glue (Patex)

The results:

UHU Plus

UHU Por

works well. good fixture and waterproof:

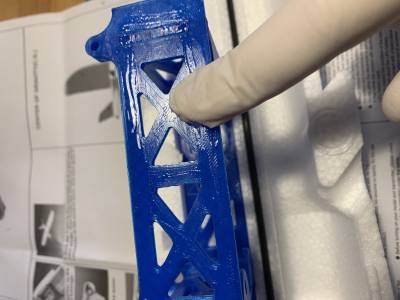

But - the glue has to be applied in the right way! It has to be thin and completely dry before putting the parts together:

Bust is to spread it equally with a (gloved) finger:

Hot Glue

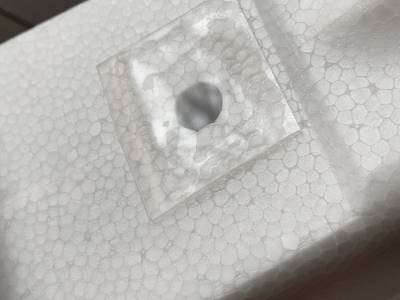

Closing holes

The so glued model had some holes to fill / close. I used thin plexi-glas. Best way to glue them was hot glue, as it can also fill little holes or irregularities in thickness.

I used the same technique also on other parts.

Waterproofing the servos

there are 2 interesting articles on Instructables on this topic:

https://www.instructables.com/id/Water-proofing-a-Servo/ https://www.instructables.com/id/Waterproof-your-servo-motors/ (if you want to follow this one, dont forget the glitter on your finger nails)

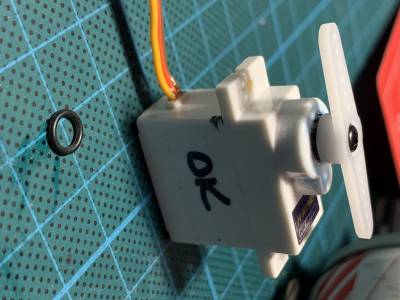

1. Make the housing waterproof

* I used “Curil”, a standard sealing compound. * Open the servo and put the sealant an all touching surfaces * also put sealant to the cable, where it leads through the housing

2. Insert a O-Ring under the horn

* remove the horn * add a 1mm thick o-ring * add some lubrication. I used “CRC Multilube” - attention - lubrication has to be compatible with the rubber of the sealant. Don't use silicon rings with silicon lubricant. * screw the horn back on

Test it...

- submerge in water while it moves - no bubbles should emerge