- Architecture and Civil Engineering

- Research

- Facilities

- Laboratories

- CAX Laboratory - Rapid Product Development

CAX Laboratory - Rapid Product Development

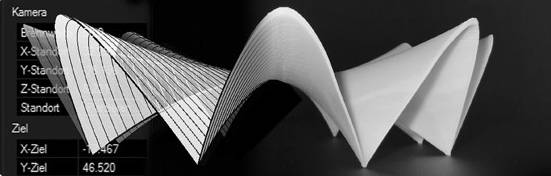

Rapid Prototyping is an umbrella term for manufacturing processes that enable the production of workpieces directly from digital data. Before plotting begins, the model is fully developed according to specified requirements and a fully functional prototype is created. The method is based on the principle of building up the model layer by layer. Depending on the complexity, very precise evaluations of the prototype can be carried out and a high degree of detail can be reached.

Shell structure by Beate Popfinger according to Fèlix Candela

Fused Deposition Modeling as a method of Rapid Prototyping generates a plastic model by heating a meltable plastic. The starting point is the computer-internal data model. Thermoplastics consisting of building material and support are applied by means of an extrusion nozzle. The nozzles are guided through an NC-controlled two-dimensional plotter mechanism. The use of support material becomes necessary in the event of component overhangs.

Fused Deposition Modeling as a method of Rapid Prototyping generates a plastic model by heating a meltable plastic. The starting point is the computer-internal data model.

Thermoplastics consisting of building material and support are applied by means of an extrusion nozzle. The nozzles are guided through an NC-controlled two-dimensional plotter mechanism. The use of support material becomes necessary in the event of component overhangs.

Contact | |

Phone: | +49 821 5586-3112 |

Fax: | +49 821 5586-3110 |