Reciprocal Shell 2023

An Innovative and Sustainable Structure in Augsburg City

Course of studies

Digital.Design and Production (BEng)Project description

The "Digital Timber Construction" Lab (DTC) has recently completed an impressive research demonstrator: a lightweight and environmentally friendly timber grid shell. This pavilion is part of the "Timber Structure Interface" (TSI) research project, funded by the Federal Ministry of Food and Agriculture (FNR) and led by Prof. Dr. Christopher Robeller.

Involved persons

The TSI team's innovative grid shell design eliminates the need for any steel nodes or special connectors, allowing for structurally efficient catenary cross-section shells and other free-form shapes previously unattainable.

The creation of this new prototype was made possible by the support of StadtSparkasse Augsburg, who invited DTC to design a structure for their annual #Stadtgewaechs summer event. The event aims to promote sustainability in the heart of Augsburg city at Moritzplatz.

Compared to the previous year's Reciprocal Shell 2022, built during an international design and fabrication workshop at Chalmers University, Sweden, the Reciprocal Shell 2023 has seen significant improvements. The span has been increased from 7m to 15 meters, and the shell's area expanded from 20 to 127 sqm. The professional timber fabrication and assembly for this larger scale were expertly carried out by CLTech GmbH in Kaiserslautern within a remarkable five-day timeframe.

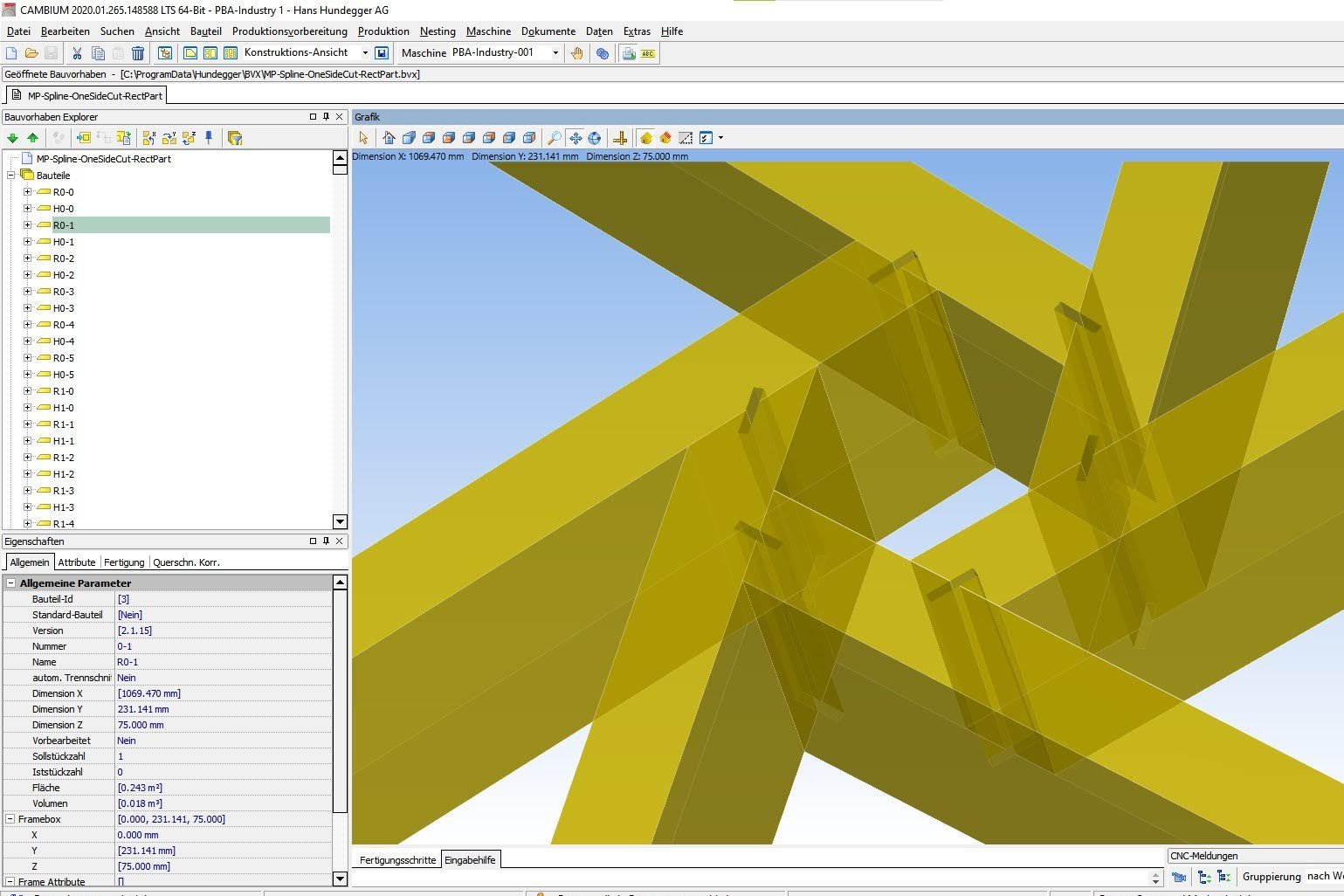

It's worth noting that while the Reciprocal Shell 2022 was constructed using a single Kuka robot equipped with a saw blade, the design team for the Reciprocal Shell 2023 decided to take a more industrial approach. They integrated modern timber construction machines to bring this unique timber system to life, aiming to bridge the gap between research and the timber construction industry.

To achieve this, the team developed a data export module in Rhino/Grasshopper, which automatically converted geometrical data to machine data, specifically a special file format for Hundegger machines. Without this algorithmic approach, the process would have been time-consuming and complex.

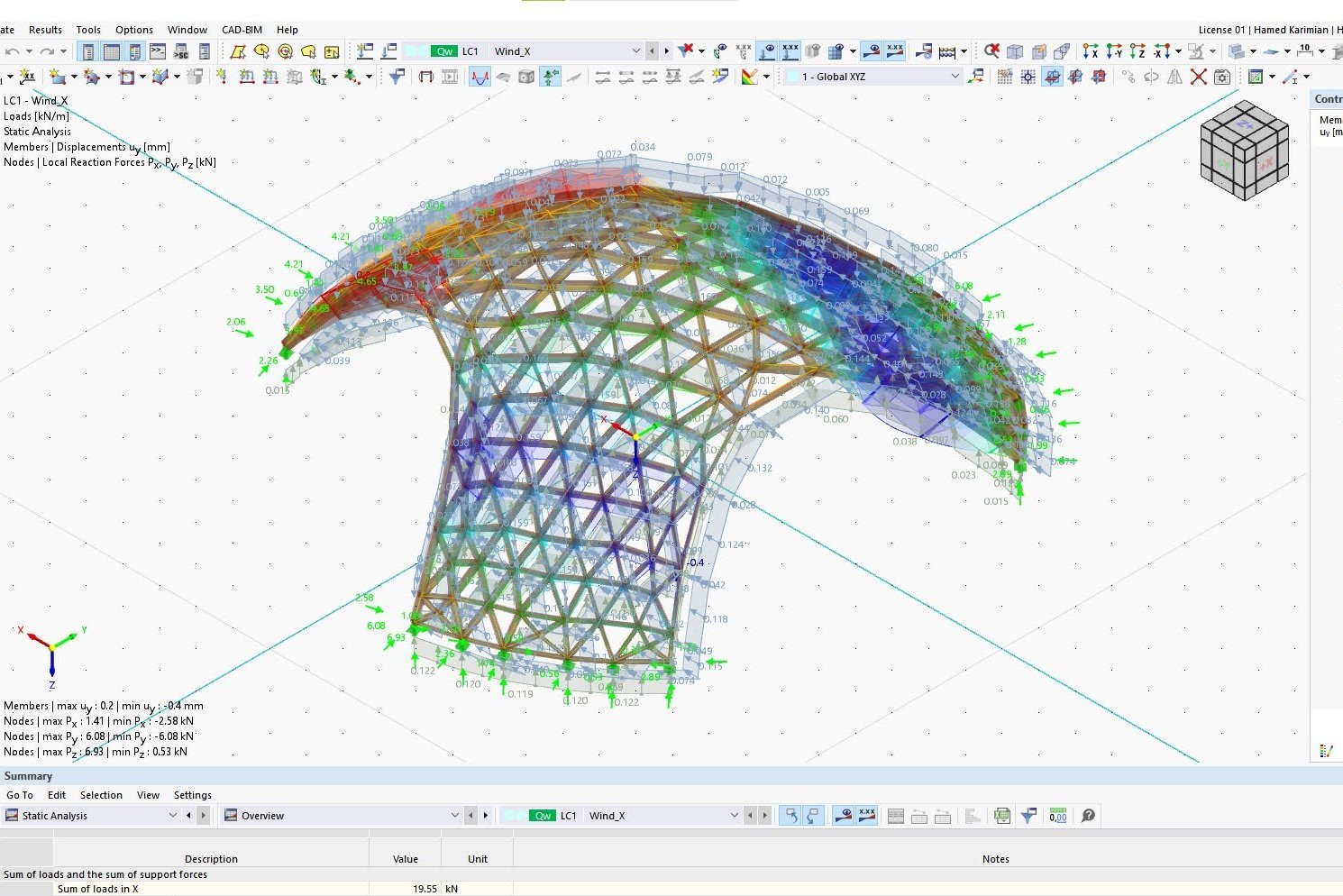

Following the smooth installation process, the structure underwent an experimental load test conducted by professional engineers from IngPunkt Co. The test ensured the stability and load-bearing capacity of the shell, with results aligning with those simulated on the Dlubal RFEM structural analysis software. The seamless export of structural data from the modeling software to the structural software was also implemented within Grasshopper.

The Reciprocal Shell 2023 will soon be disassembled for relocation. Currently, the TSI team is developing an innovative roof system to protect the timber structure for long-term use.

The success of this project would not have been possible without the incredible support of an amazing team. Special thanks are extended to StadtSparkasse Augsburg, CLTech GmbH, Dlubal Software GmbH, Agentur Sportbrain, Technisches Hilfswerk THW, Lauter Sand Kies Beton GmbH & Co. KG, Feuerwehr Lechhausen, Ordnungsamt, Bauordnungsamt, and Sozialreferat Augsburg.