ECO-CMC

Development of short-fiber-reinforced ceramics using natural raw materials and recycled materials

Project description

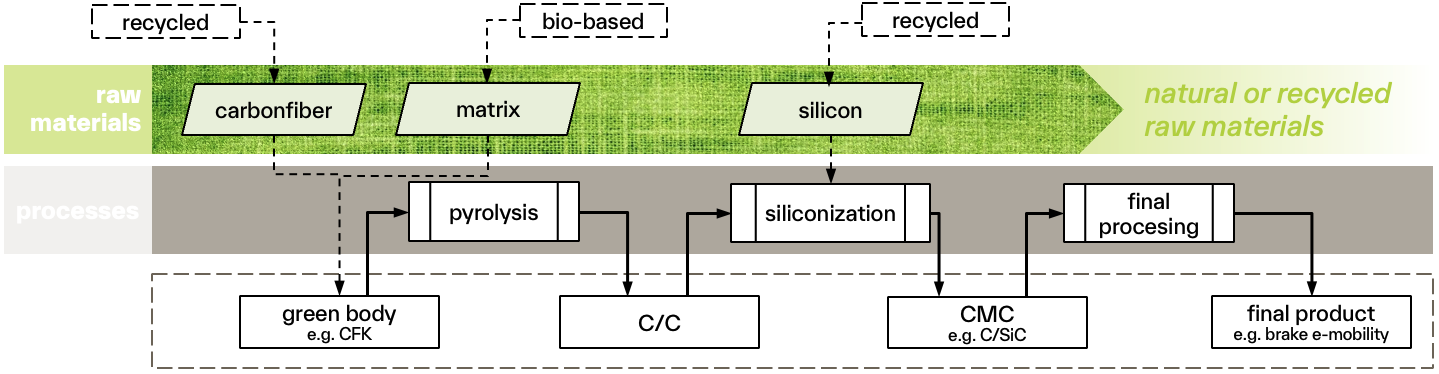

In the laboratories of the University of Applied Sciences Augsburg, the research group THA_comp Process Technologies, led by Prof. Dr.-Ing. Ralf Goller, is tackling a task of great significance: the development of short-fiber-reinforced ceramics (CMCs) using natural raw materials and recycled materials. Precise coordination of materials, processes, and production methods aims to reduce dependence on synthetic raw materials, especially petroleum, and thus make a significant contribution to solving global ecological challenges. ECO-CMC, which kicked off in the summer of 2023, is not only a significant step towards sustainable technology but also a vibrant example of innovation and technical sophistication.

Goals

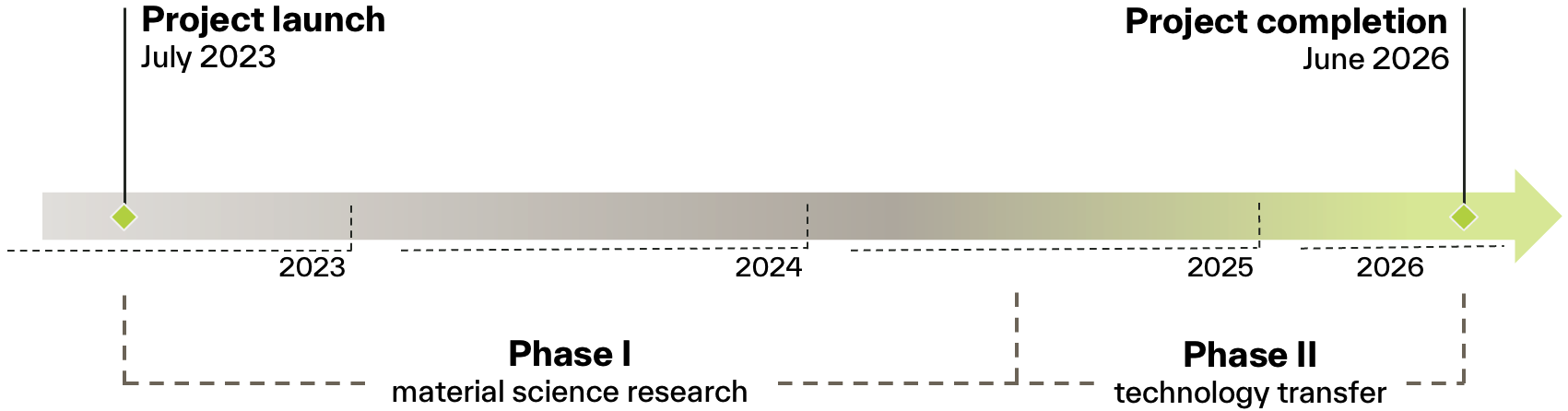

The goal of ECO-CMC is to develop a short-fiber-reinforced ceramic using natural or recycled materials. The project is divided into two phases:

Phase I: Material science research

Phase I focuses on material science research. In this phase, recycled carbon fibers (rCF), sustainable matrix systems, and processed silicon for use in CMCs will be evaluated. This includes the selection of potentially suitable raw materials, the production of test specimens, and the systematic characterization of these materials in their raw form, as well as in composite states. To assess the potential of the alternative raw materials, the material characterization will involve a comparison to established CMCs.

Phase II: Technology transfer

Upon completion of Phase I, it will be determined what technological, physical, and chemical properties the SF-CMCs produced in the project exhibit and how they compare in terms of ecological properties to established CMCs. In view of the leading application "Emergency Brake System for Electromobility" (potentially a hybrid brake consisting of CMC friction segments and a metallic base), Phase II will define the conditions for the demonstrator and produce a prototype.

The use of a hybrid brake disc allows for an optimized weight-specific performance design and contributes to resource conservation. This results in a cost-effective solution for electromobility.

Contact Person

Contact | |

Phone: | +49 821 5586-2068 |

Contact | |

Phone: | +49 821 5586-2392 |

Fax: | +49 821 5586-3160 |

Founding body

The ECO-CMC project is supported by the Alexander Tutsek Foundation.